- Furnace Safety Supervision System

- Ignition Control System

- The Ignition And Combustion Equipment

- Energy-saving Combustion System

- Combustion Test Bench

- PLC Programmed Control System

- Industrial Television Monitoring System

- Flare System

- Intelligent Online Soot Blowing System

- Acoustic Gas Temperature Measurement System(SEI)

- Compressor Optimization Control System(CCC)

http://www.nendar.com

Phone:0516-83899666

postcode:221008

E-mail:xznengda@126.com

Address:Hardware district 1 11,National University Science Park of China University of Mining and Technology,Xuzhou,Jiangsu,China

Flare System

1.NDFS relief torch head

Our company can design and produce a variety of structural forms torch burner design and processing technology in the industry-leading, widely used in petrochemical, metallurgy, environmental protection industry, the maximum diameter of up to 2500mm, material including stainless steel, high temperature alloys, and may increase Air temperature ceramic coating, greatly extending the life of the burner.

1) Two steam torch burner nozzle-plum Two steam. Steam is injected into the center to reduce the flame core temperature, precipitation and reduction of soot extend the life of the torch head.Plum use porous outer annular steam nozzle sprayed into the swirling manner, forming a curtain of steam, air ejector effectively to ensure full combustion and reduce noise. 2) three-way steam smoke and flare-type burner Three-way steam. Center steam enters from the bottom of the torch head can be premixed; all the way to the ring after the passage of the steam ejector nozzle Plum burner into the upper air, mixed with the exhaust gas atomization gas formation is conducive to full combustion; another external ring road through the large number of steam Small peripheral jet nozzle in flames further ensure full combustion. The lower part of the torch head with a silencer hood. This is very effective smoke torch head for higher carbon content of gas combustion.

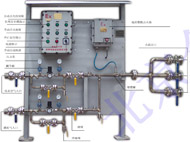

2.utomatic ignition system Process: When flare gas emissions by setting the seal pressure signal before the water to win the title of the flow signal (4 ~ 20mA), the incoming operating room console PLC (disk, cabinet, IPC), when more than set the value of the audible alarm, PLC control turn the ignition fuel pipe line solenoid valve (pneumatic valve), starting altitude torch ignition, ignite fire extinguishers, ignited long light, the main torch, the torch flame signal detected by UV flame detector, PLC control off point fire fuel gas solenoid valve (pneumatic valve), high-altitude torch igniter.PLC (IPC) can be automatically adjusted according to the steam discharge air flow control valve (also remote manual implementation), regulating the flow of steam smoke, smoke-free combustion. Control system is in standby mode. UV flame detection line detection, the system also includes automatic, semi-automatic, manual, ignition function. With UPS (3KVA) enables the system to work as usual in the state power.The control section has disc, cabinet, desktop, PC machines and other control systems for users to choose. Scene PLC can be digital or analog communication with a remote control room between DCS, the remote site related signals to DCS, DCS can also be remotely controlled ignition and flame status displays. 1) The main components -NDDH-20B aerial ignition-proof -YHT-3-type ignition barrel -NDHJ - 7 UV flame detector -DN25 explosion-proof solenoid valves (pneumatic valves) -3051 Type differential pressure transmitter (user optional) - Plug-meter (user optional) -NDDK Series Torch automatic ignition console (cabinet)

2) The main function - Site pressure, flow control signal display, sound and light alarm - Automatic adjustment of steam, nitrogen flow rate based on emissions - UV flame detection line detection, control - Automatic, semi-automatic and manual control functions - The system self-test function, the accident sound and light alarm - Business as usual case of power failure (UPS power supply) - Using standard communication protocol to communicate with the DSC system - Dynamic simulation screen, historical event logging - Data show that human-machine interface, keyboard, mouse