http://www.nendar.com

Phone:0516-83899666

postcode:221008

E-mail:xznengda@126.com

Address:Hardware district 1 11,National University Science Park of China University of Mining and Technology,Xuzhou,Jiangsu,China

Furnace Safety Supervision System

Boiler Furnace Safety Monitoring System, or FSSS (Furnace Safeguard Supervisory System), is to ensure the safe operation of boiler-critical systems, which started in the boiler, and stop running all stages of continuous monitoring of the boiler operating parameters, in accordance with provisions of Ex order security conditions, continually carry out logic judgment and calculation, the corresponding interlock device through the combustion facilities in accordance with established procedures to complete the necessary operations to avoid explosive air - in the fuel mixture accumulated inside the furnace and flue, and boiler in the event of endangering the safety of working conditions , entered the chamber quickly cut off all fuel to prevent the occurrence of explosion of a furnace.

Furnace Safety Monitoring System (FSSS) mainly by the operating station, operation panels, the main control cabinet, ignition control system, flame detector and cooling air system, and other components. Including the fuel system, throttle bodies monitoring the implementation, chamber pressure, drum level, the blower fan which, by the door, and other signal conditioning warm water monitoring, as well as with DCS communications. System structure indicative figure: -Main fuel tripping MFT (Main Fuel Trip) -Fuel oil Trip OFT -Oil leak test system -Oil combustion system management (signal detection and control) -Pulverized coal combustion system management (signal detection and control) -Rapid load-shedding Fast Cut Back -Signal detection and extinguishing the flame protection -Alarm and display (node failure, the furnace pressure drum water level alarm limits, combustion instability alarm.) -Flame detector cooling wind management -Controlled ignition (Local / Remote) -Accident causes chronicles functional movements -Recollections functional simulation curve

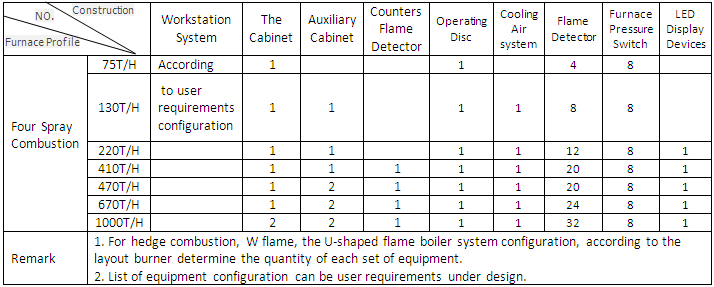

4 .FSSS system workstations main technical parameters -Analog sampling resolution:1 / 4096 -Analog sampling period:20ms/16 channel 5.system configuration Typical boiler system configuration

Supporting users to provide the following equipment: 1).FSSS workstations, and communication interfaces Annex 3).Auxiliary cabinets and I / O Interface 5).Operating panels 7). Flame detector cabinet

-Witching response time:less than 3 ms

-MFT output Contact capacity:10 A/220V AC

-Logic signal output tap capacity:0.5 A/24V DC

-Work Power:AC 220V ± 10% 50Hz

-Ambient temperature:0 ~ 50 ° C

-Environment humidity:10 to 90% RH

-Rack size:standard or user-defined

2). Logic control the cabinets

4).Power counters

6). Flame detector, Signal Processor and specific cables

8). Flame detector cooling air system: centrifugal fan of cold air, switch plate, inlet screen, on-site control cabinet of cold air, Wind pressure switch

9).Fuel systems: fuel pressure switch, the fuel pressure switch, fuel temperature switch, the mother of oil jumped valve, the valve such as recycling

10). Pressure switches for boiler: High boiler furnace pressure switch, Low boiler furnace pressure switch, High boiler furnace pressure switch alarm, low boiler furnace pressure switch alarm.